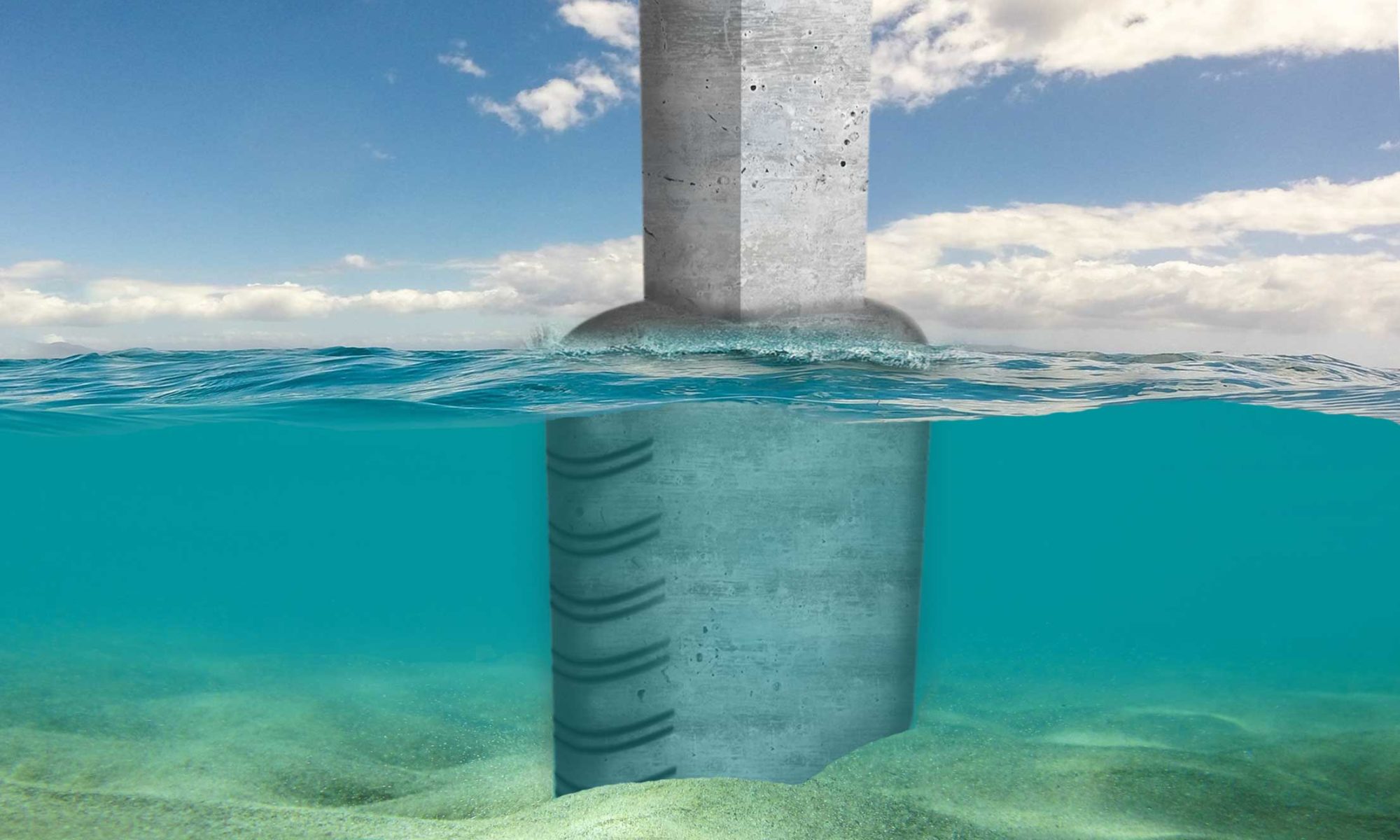

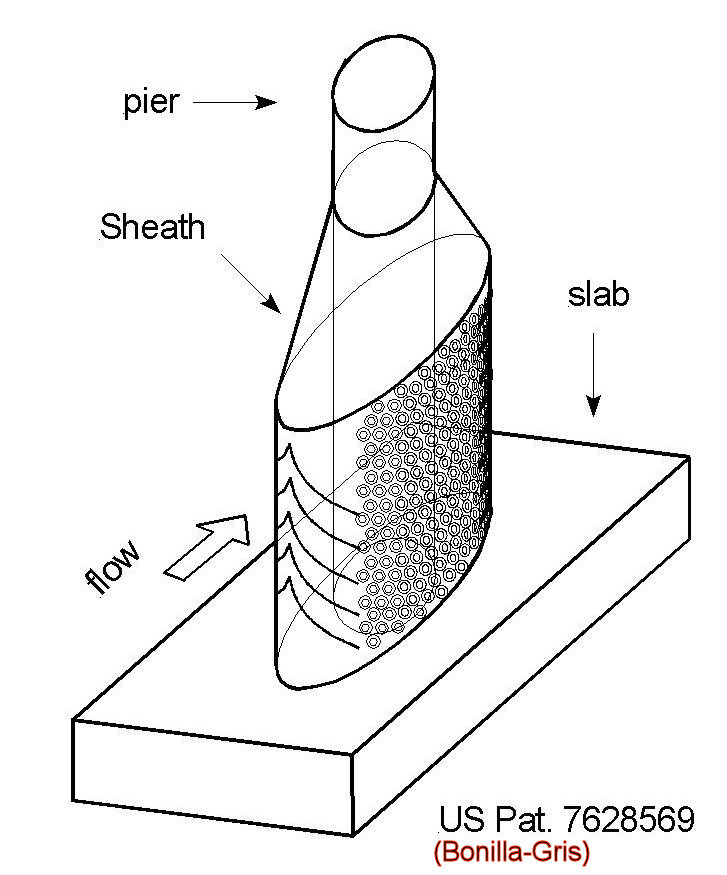

The Pier Sheath is a patented scour countermeasure; it is a next-generation device, conceived with a radically new perspective in mind, designed on solid Fluid Mechanics basis, sound engineering knowledge and personal professional experience.

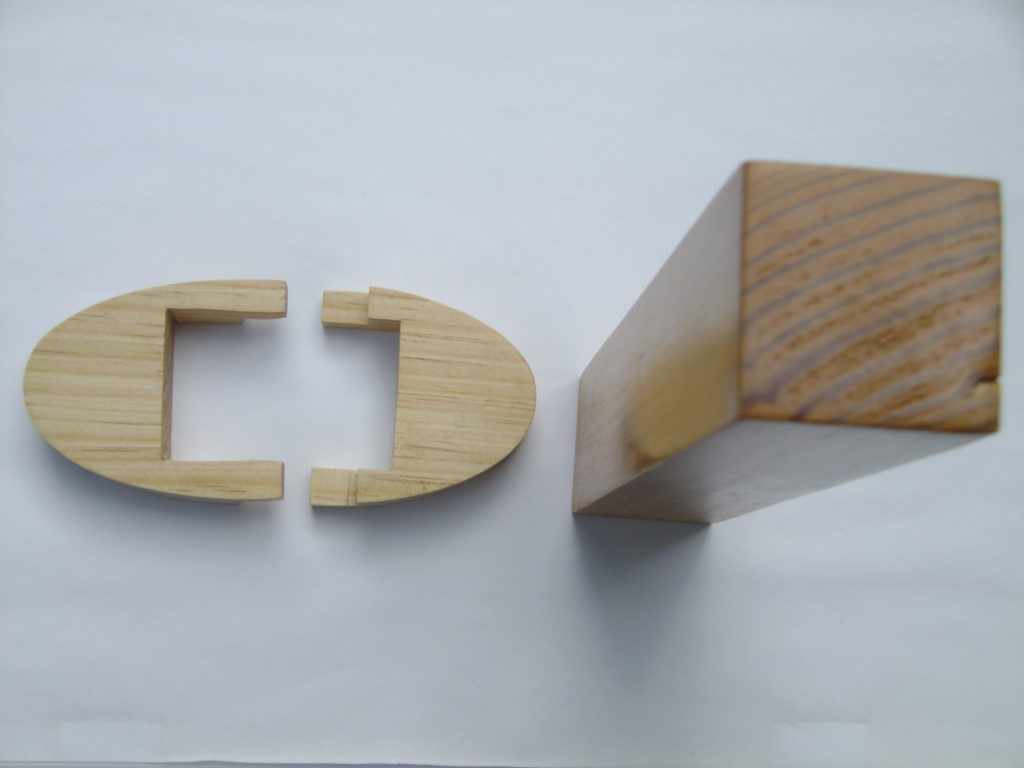

The Pier Sheath can be implemented as a collar-like modular body that can be cast in place or precast and later put around the submerged structure (Fig. 1).

The Pier Sheath breaks several current paradigms (both conceptual and technological), featuring two concurrent characteristics not yet used in this field: engineered roughness and hydrodynamic profile. It has already been extensively tested in the Hydraulics laboratory, demonstrating its efficiency in reducing local and wake vortex scour. It can potentially raise the adaptive capacity, the resistance and resilience of bridges against scour –stretching their lifetime– and increasing the safety of the bridge users.

The scour countermeasures currently used are not as effective as they should since they intend to armor the riverbed against scour (the effect) -instead of acting against the cause (the vorticity)-, introducing strange materials into the river, altering the riverine environment. Those materials can be riprap, artificial concrete elements with various characteristics, mats, filled bags, etc. In addition, those measures are susceptible to damage and so are not failure-proof: “…to be effective, most [scour] countermeasures will require a monitoring plan, inspection, and maintenance” (1)

Riprap –the most frequently used countermeasure-, for example, presents three failure modes; the extraordinary weather conditions under which these failures usually occur are precisely the riskiest for the structure. Also, as with other commonly used countermeasures, frequently, riprap must be applied in certain river conditions (low stage or dry riverbed), may need heavy equipment for installation and tend to introduce environmental impacts.

The Pier Sheath has many advantages with respect to the current bed-armoring measures; among them, the Pier Sheath acts directly against the genesis of the phenomenon, minimizing both the local and the wake vortex scour; it can resist any hydraulic condition; does not need maintenance/repair; and may be a cheaper solution.

The Pier Sheath received the 2017 Most Efficient ASCE Grand Challenge Innovation Contest Award in the Resilience category. (2)

- (1) FHWA, Hydraulic Engineering Circular No. 18, Evaluating Scour at Bridges, Fifth Ed., April 2012, p. 1.4

- (2) https://www.evernote.com/shard/s175/sh/46492115-e3dc-4b15-86f7-5ffd75f56db9/58d8357c4b013e454901713190459ccc

How can the Pier Sheath be built?

One way the Pier Sheath can be built is by installing around the pier, one over another, successive precast interlocking slabs made of lightweight concrete (or other suitable material), molded or 3D-printed, with the appropriate shape, dimensions and engineered roughness (Fig. 2). The weight and dimensions of the slabs would be such that they can be handled, hoisted and put in place by means of a light loader crane located on the bridge deck, avoiding the need of heavy equipment. The Pier Sheath can become a unity with the pier using non-washable grout. The proposed construction method is in line with the FHWA Accelerated Bridge Construction (ABC) Program.