Prof. Robie Bonilla-Gris, M.Sc., Ingénieur Hydraulicien

Retired Professor Robie Bonilla-Gris is a Civil Engineer with over 35 years’ experience as hydraulics engineering professor and researcher at the National Polytechnic Institute (IPN) in Mexico City, Mexico. He participated as researcher, coordinator (and as director, in about half of cases) in over 20 studies of experimental engineering and research carried out in the Engineering Hydraulics Laboratory of the IPN, for several Mexican federal government’s offices: CFE (Federal Electricity Commission); PEMEX (Mexican Oil); IMP (Mexican Oil Institute); SARH (Ministry of Hydraulic Resources); FONATUR (National Tourism Fund); also, studies commissioned by private companies. These studies have been used to define the technical characteristics of multimillion dollar projects such as the pump sump for cooling of a nuclear power plant; the preliminary design of a supply oil port; the definition of the sites of the monobuoys for oil delivery to tankers in the Cayos Arcas area of the Gulf of Mexico; the solution of silting problems and land reclamation in an industrial port; the hydraulic design of the pump sumps of several thermoelectric power plants; others.

Prof. Bonilla-Gris also worked in the Mexican Institute of Water Technology (IMTA), where he did research in the big pump sumps’ hydraulic design, resulting in new design criteria that have already been applied to several major pump sumps in Mexico.

Prof. Bonilla-Gris also designed the Hydraulics Laboratory of the School of Engineering of the Universidad Juárez Autónoma de Tabasco, Mexico, and has presented technical papers at innumerable Conferences over the years.

Profesor Bonilla-Gris developed, among others, the following technological improvements:

- A profile that generates low-intensity wakes, thus reducing the flow vorticity, to be applied to the end noses of the walls supporting the travelling screens in big pump sumps, like those in the nuclear and thermal power plants. The profile has allowed a reduction in the vorticity and hence in the total sump length –and the cost—in several thermal power plants in Mexico (such as Puerto Libertad, Son.; Tuxpan, Ver.; Manzanillo I and II Power Plants).

- A method for design of big pump sumps using a dimensionless parameter that relates closely the geometric features of the sump with the hydrodynamic characteristics of the flow, instead of the common use of empirical relationships obtained by statistical analysis of the length-depth-width-submergence ratios of the sumps that perform satisfactorily.

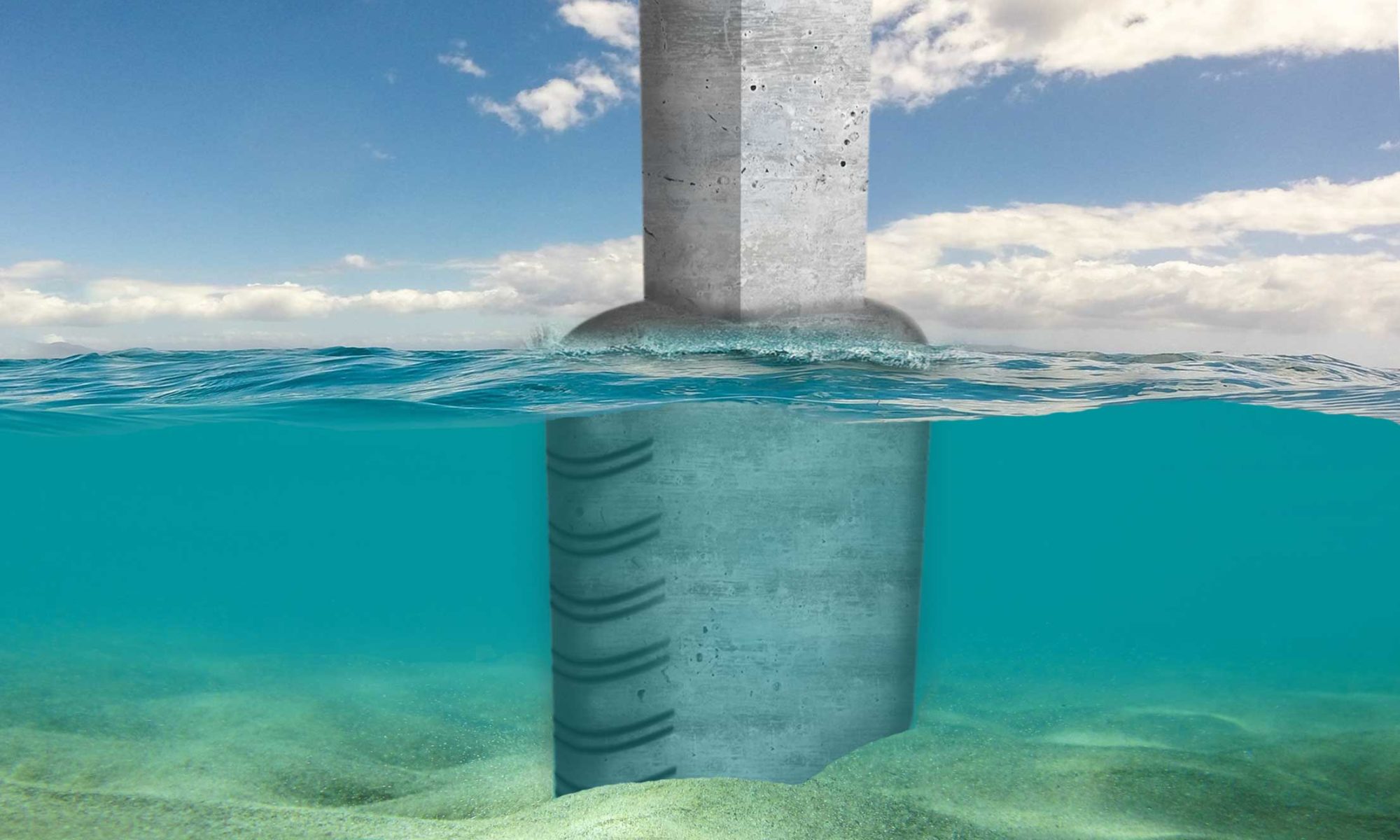

- A technique for using artificial roughness to control the boundary layer behavior and the position of the areas of flow separation in submerged bodies, to reduce vorticity and, hence, vibration and periodic forces. Applied to bridge piers and columns supporting wind turbines at sea, the roughness reduces scour.

- US Patent 7628569 “Covering element for protecting structures against scouring and drag force”

Catalina Nadeau-Bonilla, M.A.Sc., P.Eng.

Catalina Nadeau-Bonilla is a Civil Engineer with over 22 years of experience in infrastructure projects design (green field and brown field), commissioning and optimization in Canada and Mexico.

Catalina has participated in preliminary studies, predesign, detailed design and commissioning of several multimillion dollar infrastructure projects, including capacity assessments, technology evaluation and selection, Value Engineering, HAZOP analysis, technical review of detailed design, equipment specification preparation and evaluation, equipment sizing, selection and optimization, best management practices reviews, life cycle cost analysis, regulatory negotiations and compliance, project management, Standard Operations Procedures and Operation Manuals preparation, Business performance measurement and reporting, quality control systems, budget and staffing management, among many other engineering activities and tasks as a Consultant and as a Civil Servant (Private and Public sectors).